ULTRA PURE WATER

CANADIAN CLEAR ULTRA PURE WATER

Canadian Clear Offers Solutions For Ultra Pure Water Ultrapure Water (upw) Is Water That Has Been Purified To Very Strict Specifications, Containing By Definition Only H20, And H+ And Oh- Ions In Equilibrium. Therefore, Ultrapure Water Conductivity Is About 0,055 Us/cm At 25oc, Also Expressed As Resistivity Of 18,2 Mohm.Ultra Pure Water Is Mainly Used In The Semi-conductor And Pharmaceutical Industry.Ultrapure Water Production Often Is Produced Through Processes Like Membrane Filtration Or Ion Exchange To Reach The Ultimate Conductivity Of 10 Us/cm. The Demineralised Water Is Then Processed Through A High-performance Mixed Bed Or By Electrodeionization Membrane Degasification Is Used To Degasify Water

Industrial Process Water At a Glance

- Semiconductor Industry

- Nuclear Power Plants

- Pharma

- Hospitals

Semiconductor

Ultrapure water (UPW) for semiconductor industry

In the production of plasma displays, chips and integrated circuits, water of very high quality is necessary for certain process steps.

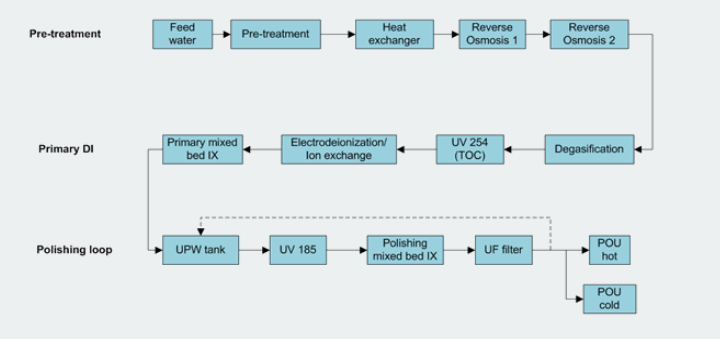

Typical scheme of a UPW production system

UPW production requires an integration of several treatment technologies including reverse osmosis, electro-deionization and ion exchange.

A well designed UPW system requires a strategic selection of technologies and equipment. Depending on the feed water quality and/or the user requirements, different configurations can be applied.Please contact us for more information.

UPW quality guidelines

The ASTM (American Society for Testing and Materials) differentiate several gradations of purity for the semiconductor industRYM

| Parameter | Type E.1 | Type 1.1 | Type 1.2 |

|---|---|---|---|

| Linewidth | 1.0-0.5 | 0.35-0.25 | 0.18-0.09 |

| Resistivity, 25o MΩ.cm | 18.1 | 18.2 | 18.2 |

| TOC (μg/L) (on-line for) | 5 | 2 | 1 |

| On-line dissolved oxygen (μg/L) | 25 | 10 | 3 |

| On-Line Residue after evaporation (μg/L) | 1 | 0.5 | 0.1 |

| SEM particles 0.1-0.2 µm 0.2-0.5 µm 0.5-0.1 µm 10 µm |

1.000 500 100<50 |

700 400 50<30 |

<250 <100 <30 <10 |

| Bacteria in CFU/Volume 100 mL Sample 1L Sample 10L Sample | 5 | 3 | 1 10 |

| Silica Total (μg/L) Dissolved (μg/L) | 5 3 |

3 1 |

1 0.5 |

| Anions and Ammonium by IC (μg/L) Ammonium Bromide Chloride Fluoride Nitrate Nitrite Phosphate Sulfate |

0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 |

0.1 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 |

0.05 0.02 0.02 0.03 0.02 0.02 0.02 0.02 0.02 |

| Metals by ICP/MS (μg/L) Aluminum Antimony Arsenic Barium Boron Cadmium Calcium Chromium Copper Iron Lead Lithium Magnesium Manganese Nickel Potassium Sodium Strontium Tin Titanium Vanadium Zinc |

0.5 0.5 0.3 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 |

0.02 0.02 0.2 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 |

0.002 0.002 0.002 0.002 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 |

Note: The values in this table are guidelines provided by ASTM. The guidelines will be revised whenever the semiconductor industry develops new linewidths Please consult ASTM website for updates on these values. The requirements of high-end use are classified in type E-1.1 and type E-1.2.