MEMBRANES

REVERSE OSMOSIS MEMBRANES ELEMENTS

Efficient Use Of Water Resources Is An Important Challenge For Using The 21st Century. A Global Shortage Of Water Resources In Expected. And Consideration Of The Earth's Environment Has Become More Important In Recent Years, Giving Rise To A Growing Demand For Reverse Osmosis Membranes. To Excel In Quality And High Performance, Canadian Clear Is A Functional Membrane Element That Was Engineered Through In-depth Technical Parameter. Involving Technology From the United States Driven Through Membrane Specialists And years Of Research And Development In Polymer Engineering Resulted In The Birth Of Canadian Clear Reverse Osmosis Membrane.

WATER TREATMENT BY MEMBRANE SEPARATION TECHNOLOGY

- Membrane Separation Processes In Current Us Include:

- Reverse Osmosis (Ro)

- nanofiltration(Nf)

- ultrafiltration(Uf)

- microfiltration (Mf)

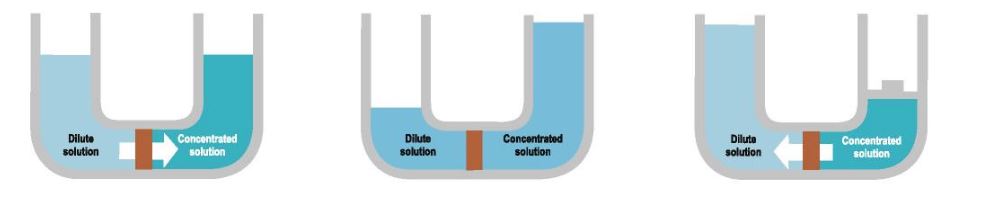

Principle of Reverse Osmosis:

- When A Dilute Solution And A Concentrated Solution Arc Partitioned By A Semi-permeable Membrane, The Solvent (Water In This Case) Passes Through The Membrane From The Dilute Side Into The Concentrated Side.This Phenomenon Is called "Osmosis".

- When The Osmosis Reaches A State Of Equilibrium, The Difference In Pressure Between The Two Solutions Is Called "Osmotic Pressure."

- When A Pressure Greater Than The Osmotic Pressure Is Applied To The Concentrated Side, The Solventwillflow Into The Diluteside, That Isinthe Directionopposite Toosmosis. This Phenomenon Is Called "Reverse Osmosis"(Abbreviated As"Ro")

Features of Reverse Osmosis:

-

Removal Of Dissolved Salts :

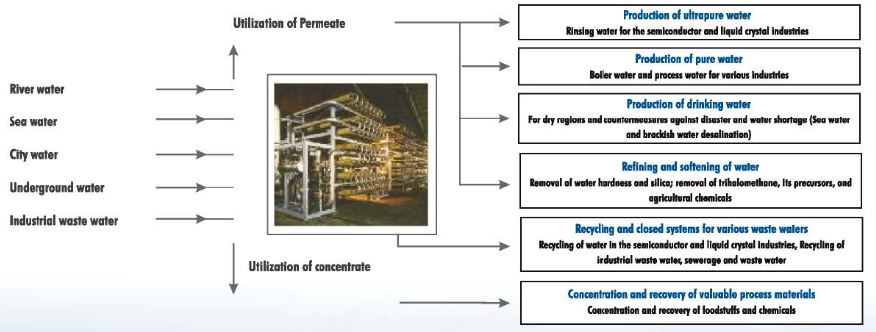

Reverse Osmosis Can Effectively Remove Dissolved Salts, Dissolved Organic Substances (Trihalomethane, Its Precursors, Agricultural Chemicals, Etc.), And Microfine Particles (Living Bacteria, Dead And Many Other Microfine Particles} From Water. Thus It Is Ideal For A Wide Area Of Applications Ranging From Production Of Ultra Pure Water To Desalination Of Seawater.

-

Energy-saving Separation Technique :

Since Reverse Osmosis Does Not Require The Evaporation Of Water,it Consumes Less Energy Than The Separation Processes That Use Evaporation.

-

Utilizable As A Concentration And Recovery Method :

Reverse Osmosis Does Not Need Heating, So It Can Concentrate And Recover Valuable Process Materials Dissolved In A Solution Without Any Degradation Which Might Otherwise Occur In Such Materials.

-

Compact Configuration :

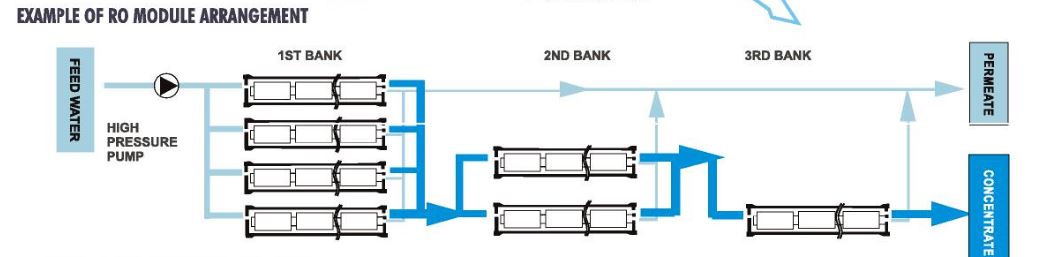

Modules Can Be Arranged In A Three-dimensional Configuration To Provide Excellent Space Efficiency Sothespace Neededfor Installation Can Be Minimized.

-

Simpie Operationandcontrol :

Reverse Osmosis Systems Are simple, Making Them Easy to Operate And Maintain.

Reliable Technology For Water Production [+]

-

Cross Linked Composite Membrane :

Electric Power Costs Can be reduced to a great extent since this membrane operates at low pressures.

It has excellent properties for removing dissolved salts,TOC and silicam, demonstrating superb preformance in the production of sea water.

-

Asymmetric Cellulose acetate membrane :

Due to non-changed membrane and unique element configuration,pretreatment can be carried out easily.

The Membranes can be used in a continuous chorine sterilization process.

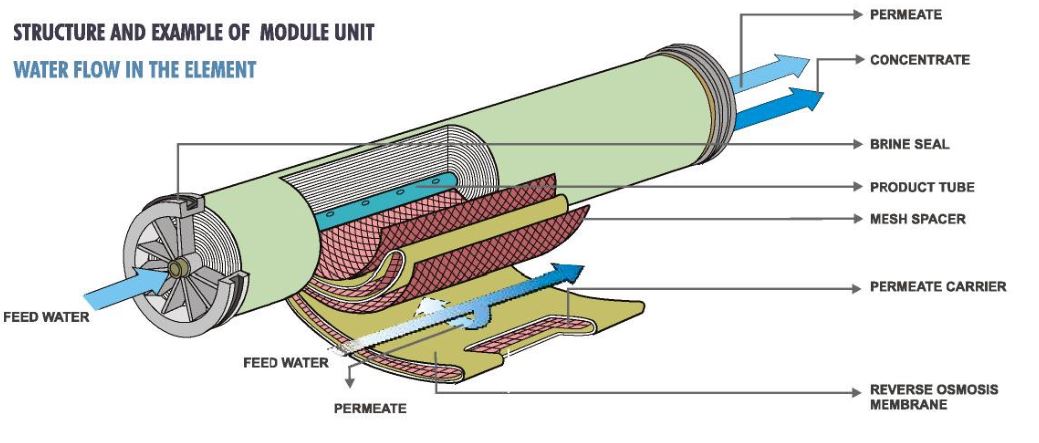

- Spirallywound Reverse Osmosis element.

- Littleelution occurs from the materials that form the element. This allows the specific resistance and TOC rise time to be reduced in ultra-pure water.

- inner-connector type elements.

- inner-connector type elements are becoming the mainstream in the global market.

- The membrane area has been expanded, surpassing that of the series.

Cross Linked Polyamide Composite Membrane element

LP-series

Structure And Example Module unit [+]

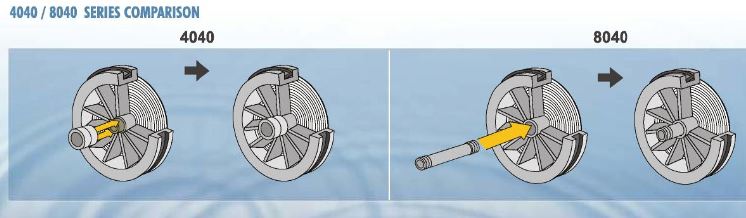

4000/8040 Series Comparison:

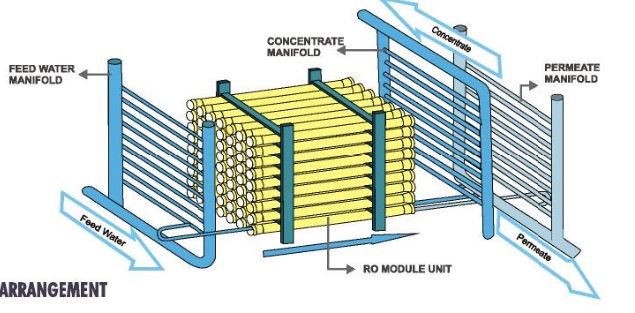

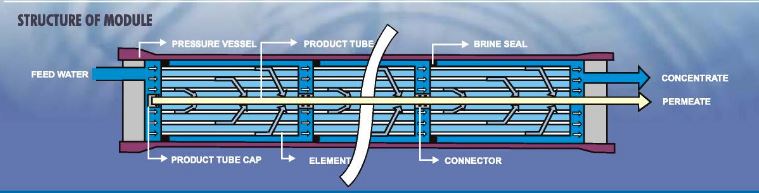

Structure Of module:

Example Of module Arrangement:

Canadian Clear Membrane Applications [+]

Major Membrane product series

Extra low pressure composite RO membrane elements

XLP series membrane can, under the conditions of extra low operating pressure, obtain as high permeate flow and rejection rate as the regular low-pressure membrane. Is operating pressure is approximately half that of the regular low pressure composite membranes, and it can reach the rejection rate as high as 99.0 percent.

Ultra low pressure composite RO membrane elements

ULP series membranes can, under the conditions of extra low operating pressure, obtain as high permeate flow and rejection rate as the regular low-pressure membrane. Is operating pressure is approximately 2/3 to the operating pressure of the regular low pressure composite membranes, and it can reach the rejection rate as high as 99.0 percent.

Low pressure composite RO membrane elements

LP series is mainly applicable to the brackish water desalination and enjoy the characteristics of low pressure operation, high permeate flow and excellent desalination property. For the more with excellent property of elimination the soluble salts. TOC and SiO2, it is especially suitable for the preparation of high purity water in electronic and electricity industries.

Sea Water desalting composite RO membrane elements

Designed for the sea water desalination, the SW series can increase the permeate flow by improving the structure of membrane elements, thus decreasing the consumption of membrane elements. It enjoys the characteristics of high rejection rate stable function low operation cost and low investment in equipment, and can assure drinking water is obtained from sea water only through one stage RO. In connection with the considerably inferior conditions of feed water such as waste water recycling and sewage water, the company can provide the following:

Fouling Resistance Composite RO Membrane Elements

The FR series is mainly applicable to brackish water desalination and is designed for the condition of fairly inferior water quality. By adopting special processing technology, the membrane surface is specially treated to change the electric charge and the smoothness of membrane surface and to increase the hydrophilicity of membrane surface, thus reducing the adhesion of contaminant and microbes to the membrane surface, decreasing the contamination of membrane elements and therefore prolonging its service life.