INDUSTRIAL PROCESS WATER

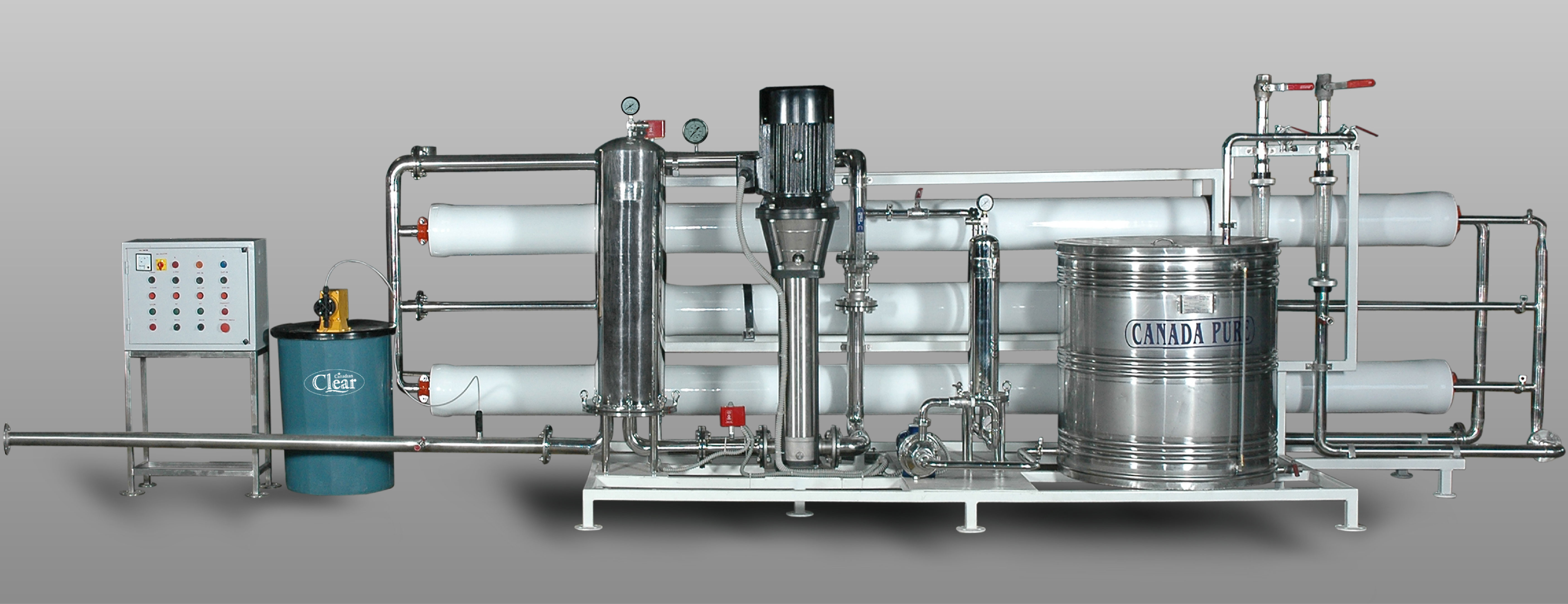

INDUSTRIAL PROCESS WATER TREATMENT PLANT

Industries We Serve

- Sugar

- Textile

- Automotive

- Cement

- Chemicals

- Electronics

- Food and Beverage

- Fertilizers

- Mining and Minerals

- Pulp and Paper

- Pharma

- Refinery and Petrochemicals

- Power

- Steel and Metallurgy

- Municipal

- Hospital and Hotels

At Canadian Clear, our extensive portfolio of custom-engineered water treatment processes sets us apart as one of the few global companies capable of offering single-point responsibility for turnkey projects. Whether for boiler feed water, heating and cooling water, or process steam generation etc... our solutions deliver maximum flexibility and value to our esteemed clients. At Canadian Clear, we offer high-performance, customized treatment solutions for a wide spectrum of industries. Our systems are engineered to help clients consistently meet increasingly stringent regulations, while also enabling closed-loop processes and product recovery, a growing priority in modern manufacturing.

With decades of experience in industrial water treatment, Canadian Clear has built a solid foundation of technical expertise. This knowledge is applied to ensure the technical and economic optimization of every system we design and implement.

Our treatment processes incorporate a combination of Physico-chemical treatment, Advanced Filtration with Membrane technologies and Biological processes

Our systems offer significant advantages, including Water reuse and near-zero discharge, Compact design with minimal footprint, Reduced operational costs

Canadian Clear continues to lead through innovation, offering the most advanced, cost-effective, and space-efficient solutions. Our focus remains on fulfilling client objectives, reducing capital and operating expenses, and contributing to sustainable water management globally.